We often hear that the packaging materials are divided into EPE and EPS , but do you know any difference between them? How is the protection of the product different?

1.EPE (Expandable Polyethylene): polyethylene foam plastic, commonly known as pearl cotton .

Features: small density, good flexibility, high recovery rate; shock resistance is better than polystyrene plastic; has an independent bubble structure, low surface water absorption; good penetration resistance; acid, alkali, salt, oil and other organic solvents , Excellent aging resistance; no flow at high temperature, no brittleness at low temperature.

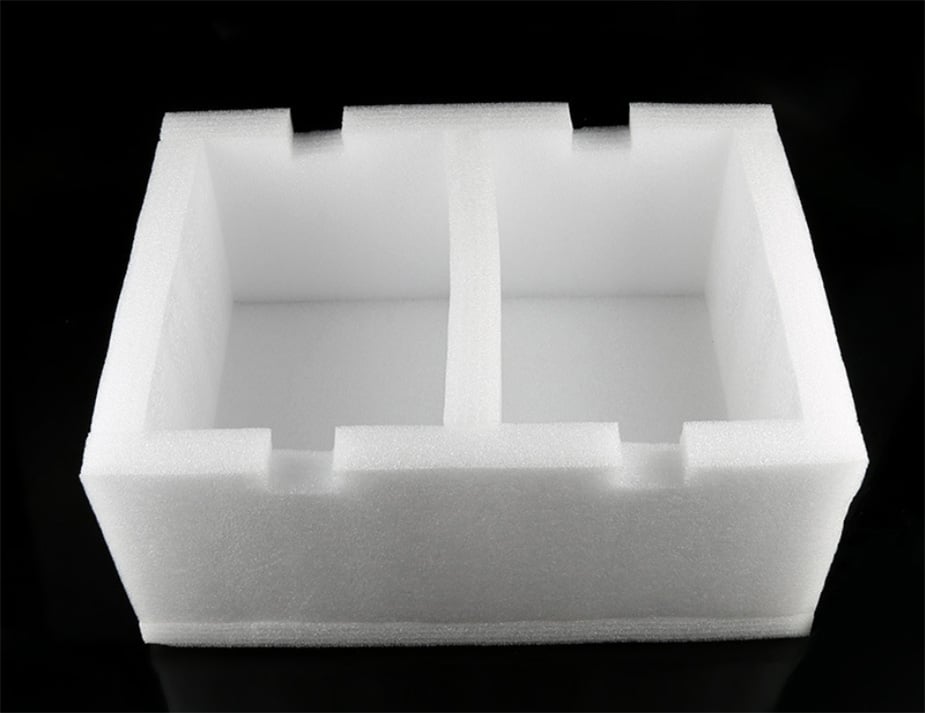

EPE

Customized EPE

EPE sheet

EPE pipe

2. EPS (Expanded Polystyrene): Polystyrene foam is a light-weight polymer.

The polystyrene resin is added with a foaming agent, and heated at the same time to soften and generate gas to form a rigid closed-cell foam. This uniformly closed cavity structure makes EPS have the characteristics of low water absorption, good thermal insulation, light quality and high mechanical strength.

EPS

Styrofoam box

Styrofoam

Styrofoam

The difference between the two:

1. Different buffer performance

1. EPE can be extruded or foamed, can be made into sheet, sheet or tube, and then stamped, cut and bonded to form, with good toughness, not easy to break, and good cushioning performance.

2. EPS can be molded, that is, it can be pre-expanded into particles, and then formed into various shapes in the mold. It has not good toughness, easy to break, and general cushioning performance.

Second, the ingredients are different

1. EPS is expanded polystyrene, a kind of thermoplastic material, which is often seen in our lives, for example, the kind of “white foam plastic” that is usually used for shockproofing in the boxes we package when we buy home appliances. “It is EPS material. The price is cheaper.

2. EPE is foamed polyethylene, which is a new type of environmentally friendly material, that is, pearl cotton that we usually talk about. EPE is made of low-density polyethylene grease through a physical foaming process to produce a non-crosslinked closed cell structure. EPE can be recycled and recycled, allowing a certain amount of EPE recycled material (70%) to be matched in the manufacturing process, so it is better for the environment and is also conducive to reducing manufacturing costs

Applications

1. EPS is mainly used in the packaging of household appliances and industrial products.

2. EPE is mainly used in the fields of high-end furniture, household appliances, instruments, craft gifts, wood products, glass ceramics, building waterproofing, carpet interlayer, sound insulation, travel bags, precision parts and accessories, and various pipeline insulation.

List of major foam materials

We also have new cushioning packaging materials, which are environmentally friendly, do not take up space, and save costs

If you have any questions, please contact us

- LINE ID: @ whu6111z

- Customer Service Hotline: 02-26980080

- Please read the shopping instructions / after-sales service before placing an order

- Customer service time: Monday to Friday 9: 00-18: 00

- Sixth, Japan, national holidays (according to public holidays) leave.

- Shipping time: Monday to Friday at 14:00 (after the order is shipped the next day, it will be delayed during holidays)

- For e-commerce companies that need to purchase in large quantities, please contact customer service (◕‿◕✿)

related articles

Related packaging materials

![EPE Shumei cloth bag [500pcs / bag] Also known as Shumei cloth pearl cotton bag, pearl cotton board, Shumei cloth bag, EPE pearl cotton, more comfortable. Since the pure pearl cotton material is very easy to break, it is necessary to add a layer of PE film on the pearl cotton to increase the tensile properties and tear resistance. It is a new type of packaging cushioning material to achieve the function of protecting products. This packaging material is safe and non-toxic, and it is a packaging material you can trust.](https://www.xiang-hao.com.tw/wp-content/uploads/2019/11/1625-1-300x300.jpg)