|

|

Many people only know that the air column bag has a good buffer protection effect, suitable for use in transportation, storage, delivery and other channels, but do not understand how the air column bag is produced? What is the composition of the air column bag so that the bag filled with gas can protect the product? Because of this, many users who are considering using air column bags have not made up their minds to choose air column packaging. |

|

| In fact, the composition of the cushioned air column bag is very simple, which is why the air column bag does not require cushion packaging such as pearl cotton, foam, etc. In production, it needs to make a mold to form the production. The air column packaging constitutes only five parts, |

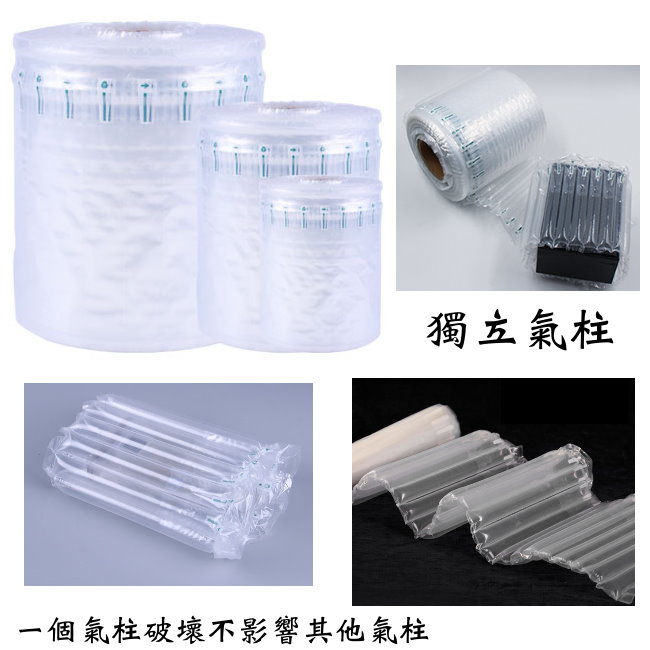

| First of all , the main body of the cushioned air column is the air column. After each gas column is filled with gas, it can protect the safety of the product in various environments. It uses gas as a support to reject all undesirable vibrations and frictions to the product. Each air column is the most important part of the buffer air column packaging. |

|

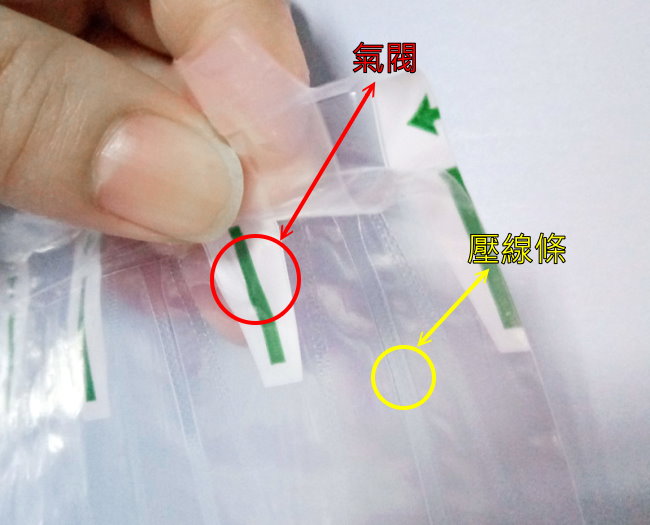

| Then there is the air valve. The air column packaging uses a reverse air valve. It is the most important and basic component of each air column bag. Without it, the gas in the air column bag cannot be locked and cannot be locked. The safety protection of the product is implemented, and its effect is to control the air not to enter but only to let the air enter the air column. Therefore, each type of air column package can be used directly without sealing after being inflated. The airway is closely connected with the air valve. The main function is to allow other middle air valves to enter the air passage through the air passage to each air column until the air column is completely filled with air. |

|

| Among the components of the air column bag , another part is very important, that is, the pressure line and the pressure point. The pressure line is equal to the lines between the air columns, usually only 1-2 mm, to block the air of each air column, the effect is that even if a single air column breaks, it will not affect the leakage of other air columns. The pressure point is the most important part for the air column bag to meet the size and needs of each product. Its function is to make the air column bag can be made to conform to the shape of the product according to the pressure point. The use of the pressure point is also why the air column bag packaging not required mold can be produced, as long as the pressure point column pouch product according to the size of the segment, when the column packing filled gas after the sustain packaging to conform to the shape of the product. |

|

| As the application of air column bags is becoming more and more popular, customers who are choosing air column bags as product transformation packaging can look at this article to understand the composition and structure of air column bags, so that you can decide whether the air column bag is suitable for your product. . |

| ■ If you have any questions, please contact customer service, there will be someone to serve you ~ ^^ |

| Northern buffer packaging material supplier|Xianghao buffer packaging| |

| ■ LINE ID: @ whu6111z (If you join Lai’s official website, everyone will serve you) |

| ■ Customer service time: Monday to Friday 9: 00-18: 00 |

| ■ Customer service hotline: 02-26934697 / 0979-987065 |

| ■ Six, Japanese and national holidays (according to public holidays) leave. |

| ■ Our company’s packaging products can be customized size / printing can contact customer service hotline |

|

Cushion Packing Materials|Cushion Manufacturing Machine|Cushion Cushion Bag|Manual Filling Bag|Vacuum Preservation Machine & Bag|Air Column Bag|Breaking Bag|Heavy Parts Bundling Tape & Related Accessories |