The purchase of packaging materials is generally considered based on cost, performance, and occupied warehouse space. Each product has its own unique advantages, and of course there are relative disadvantages. Modern society is increasingly advocating environmental protection and progress, and attaches great importance to environmental protection in the packaging industry. Who will be the darling of packaging materials in the new trend of 2020 !? The following analysis and comparison of the advantages and disadvantages of EPS, EPE, EPU, PE, let you quickly understand !!

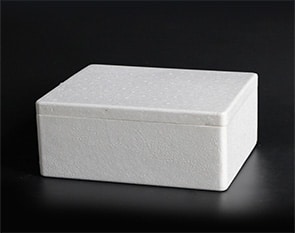

1.EPS , commonly known as foam board or Styrofoam (polystyrene / foam material)

Advantages: better shock-absorbing cushioning performance, higher compressive strength, less water absorption performance, anti-grease, easy to form.

Disadvantages: need to be made of mold, easy to produce plastic deformation after compression, poor reusability, poor weather resistance, brittle texture, easy to break and dust Packaging products cannot be recycled after use, causing white pollution. Styrene gas that emits polluted environment when burned is banned internationally.

Price: Low price.

Application: Packaging of household appliances and industrial products.

2.EPE, commonly known as pearl cotton foam (polyethylene / foam plastic)

Advantages: It has high elasticity, toughness is not easy to be brittle, and the protective interior material is environmentally friendly and can be recycled and reused.

Disadvantages: need to be cut, molded, and the empty volume inside the carton is relatively large, which not only wastes packaging materials, but also wastes shelf space, transportation space and storage space. The relatively large packaging form often creates an illusion that causes consumers I think that the volume of the product is similar to the volume of the packaging carton, which will be mistaken for deception.

Price: Because of density, this determines that its price is generally about 3 times that of the bubble

Application: box lining, life jacket, heat insulation, moisture proof, packing inner packing, etc.

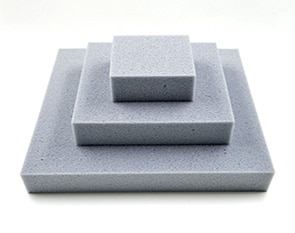

3.PU , sponge ( polyurethane / foamed plastic )

Advantages: It has the characteristics of heat preservation, heat insulation, sound absorption, shock absorption, flame retardant, anti-static, good breathability, etc., so it involves various industries, including the automotive industry, battery industry, cosmetics industry, bust underwear manufacturing and high-end furniture manufacturing, etc. .

Disadvantages: need to be cut, molded, small carrying capacity, narrow scope of application, can not be used for heavier product packaging.

Price: Because of the density, this determines that the price is generally about twice that of the bubble.

Application: Polyurethane foam material has the characteristics of anti-mildew, anti-corrosion, anti-insect, sound insulation, heat insulation, etc., water and oil filter sponge, water-absorbing sponge, non-water-absorbing sponge, cushioning and packaging of molded products

4. PE, plastic (polyethylene) mainly refers to raw materials. The plastic bags we usually use are made of this kind of raw materials. Including HDPE (High Density) and LDPE (Low Density) are polymers formed by polymerizing ethylene monomers. Odorless, non-toxic, feels like wax. It is insoluble in common solvents at room temperature, has low water absorption and excellent electrical insulation. PA + PE (nylon, polyethylene) is more flexible, sticky, and durable.

Advantages: light weight, environmentally friendly materials, good shock absorption and shock absorption performance of inflatable bags, no space consumption, not easy to be limited by product volume, inflatable bags are modern high-tech new cushion products, which are safe, beautiful, convenient and volume The advantages of being small are all in one. Covering the product closely can protect the packaged product, not just filling and supporting. Compared with the traditional filler, it will not be damaged due to the large gap in the inner box of the package, and the items will often be displaced during the transportation process. Even if it is squeezed by external force, the close-fitting design of the air bag can use the air cushion to disperse the pressure to avoid damage . More convenient, it does not require expensive and large equipment, and it is easy to make inflatable bags by the small bubble cloth making machine at home in the factory.

“Now all major industries have adopted inflatable bags as buffer packaging materials for the 2020 trend.”

The above are common packaging materials . With the advancement of technology, cushioning materials are constantly changing and innovating.

But the basic characteristics of the cushioning material will not change:

1. Absorbability

The cushioning packaging material should be able to absorb the energy generated by the impact, and have the corresponding absorption of impact energy and vibration. However, it should be noted that the absorbency of the material should be adapted to the impact energy received. It is not the better the material with the greater absorbency; at the same time, it should also have the ability to absorb the external force of vibration and dampen the vibration.

2. Resilience

The buffer packaging material will produce a certain deformation after being loaded. When the applied load is removed, the deformation of the material should be able to recover to its original shape, which is restorability. Cushioning materials must be resilient. Materials that absorb large amounts of energy and have poor resilience should not be used as cushioning materials.

3. Adaptability

Buffer packaging materials have a wide range of adaptability to temperature and humidity. The buffer material should have wide temperature and humidity adaptability, and can maintain its good buffer performance when the environmental temperature and humidity fluctuate greatly, so as to ensure that the product is not damaged during transportation, loading, unloading and storage.

4. Environmental protection

The buffer packaging material is pollution-free and conforms to modern environmental protection trends. Because low-density polystyrene is made of environmentally friendly materials, which is usually called degradable materials, certain additives need to be added, such as photodegradation, photodegradation catalysts are needed; if biodegradation is needed, starches and the like need to be added Promote biodegradable substances. However, these materials all require costs. Together with these costs, the cost of environmentally friendly materials is much higher than that of non-environmentally friendly materials.

On the other hand, making recyclable packaging is the same, and its cost is higher than non-recyclable materials.

The above is all the answers to the “common packaging materials”, I hope to help everyone.

If you have any questions, please contact us

- INE ID: @ whu6111z

- Customer Service Hotline: 02-26980080

- Please read the shopping instructions / after-sales service before placing an order

- Customer service time: Monday to Friday 9: 00-18: 00

- Sixth, Japan, national holidays (according to public holidays) leave.

- Shipping time: Monday to Friday at 14:00 (after the order is shipped the next day, it will be delayed during holidays)

- For e-commerce companies that need to purchase in large quantities, please contact customer service (◕‿◕✿)