Many people only know that gas column rolls and red wine gas column bags have good buffer protection effect, suitable for use in transportation, storage, delivery, etc., but do not understand how gas column bags are produced?

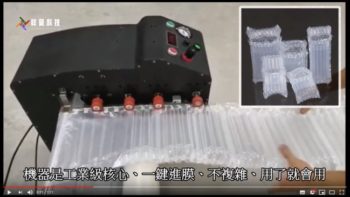

Now you can make air column rolls and red wine air column bags without introducing large-scale machines, without wasting packaging materials and space. The air column bag manufacturing machine is compact, durable, durable, industrial-grade core level, more convenient to use, not occupying space, and simpler to operate. One button to enter the film and one button to play

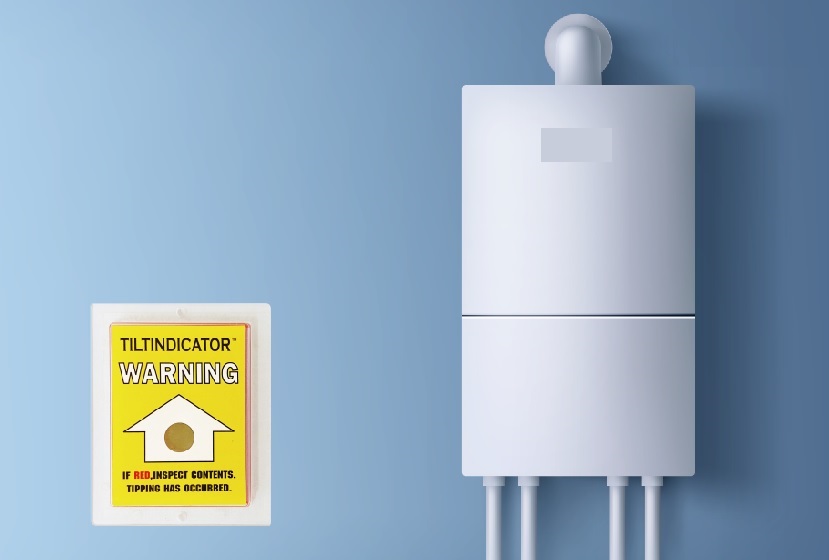

The reason why the air column packaging will be loved by the public is that it can be made into various bag types according to the product, such as Q-shaped bag, L-shaped bag, U-shaped bag, straight corner, two-end clip, etc. Moreover, the air column bag made according to the size of the article is more effective in protection.

The air column packaging is made of high-tech technology and environmentally friendly materials. The non-inflated packaging bag is completely flat, reducing the huge space occupied during transportation, reducing the loss during transportation, and reducing transportation costs, storage costs and labor costs. Air column packaging widely replaces existing inner packaging materials, such as Polyron, EPE, corrugated paper, pulp injection molding and other inner packaging materials, which not only protects the environment, saves costs, improves the efficiency of the production line and provides the most complete seismic protection of the product.